The Future of Cabinet Materials: Why PET Film Is Becoming a Global Standard

09 Dec,2025

09 Dec,2025

As cabinet design continues to evolve, material expectations are rising even faster. Today's consumers, designers, and manufacturers prioritize not only aesthetics and durability but also environmental responsibility. This shift has encouraged the industry to reconsider traditional materials like PVC foil, lacquer, and melamine. One material, however, is rapidly becoming the global benchmark for modern cabinets: PET Film.

Across Europe, North America, and Asia, PET Film is being recognized as a future-ready surface material—balancing visual appeal, performance, and sustainability in a way few alternatives can achieve.

1. Aesthetic Flexibility for Modern Cabinet Trends

From soft-touch ultra-matte surfaces to elegant high gloss, warm woodgrains, and contemporary solid colors, PET Film offers a level of design flexibility that few materials can match.

Its surface consistency, refined texture, and stable color reproduction make it ideal for modern kitchens, wardrobes, and living space cabinetry.

As minimalism and clean lines continue to dominate global interior trends, PET Film provides the perfect combination of sophisticated look + functional performance.

2. Key Advantages of PET Film for Cabinet Applications

Cabinets endure daily use—especially in kitchens. PET Film excels with:

- Superior scratch and abrasion resistance

- Anti-fingerprint performance (especially matte)

- Excellent stain and chemical resistance

- UV stability that minimizes yellowing or fading

- Non-porous surfaces that keep dirt from penetrating

The result: longer-lasting cabinet surfaces with minimal maintenance.

3. PET Film: A More Environmentally Responsible Choice

This is where PET Film truly stands out.

While many traditional decorative materials contain plasticizers, formaldehyde, or chlorine-based components, PET Film is inherently a cleaner and safer option.

Why PET Film Is More Eco-Friendly:

✓ 100% Recyclable Base Material

PET (polyethylene terephthalate) is globally recognized as a recyclable polymer.

Unlike certain foils that cannot be processed through existing recycling systems, PET can return to the circular economy.

✓ No Chlorine, No Dioxins, No Plasticizers

PVC and some conventional foils may release harmful substances during production or disposal. PET Film avoids these risks entirely, making it safer for:

- Production workers

- Installers

- Homeowners

- The environment

✓ Low VOC and Odor-Free for Indoor Spaces

Modern kitchens and wardrobes require materials that support healthy indoor air quality. PET Film's low-VOC formulation makes it suitable for homes, schools, hotels, and commercial spaces.

✓ Highly Energy-Efficient in Long-Term Use

Because PET Film surfaces are:

- Long-lasting

- Resistant to damage

- Easy to clean

They significantly reduce the need for replacement, refinishing, or harsh cleaning chemicals—contributing to a lower environmental footprint throughout the product's lifecycle.

4. Flexibility in Manufacturing: Sheet & Roll Formats

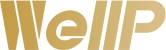

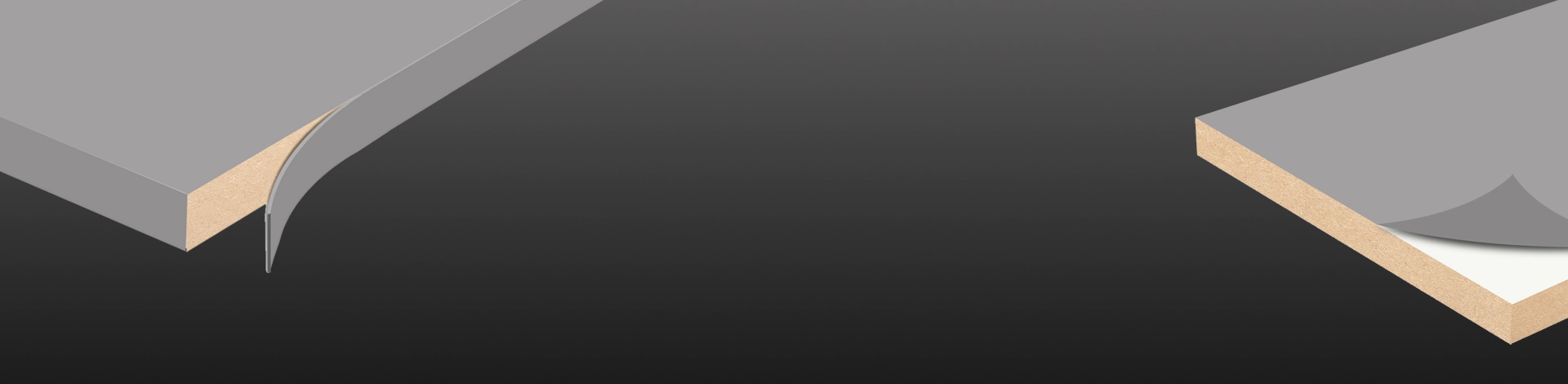

PET Film adapts easily to multiple cabinet production methods:

- Flat Lamination (PET Film Sheet): Ideal for doors, drawer fronts, and flat panels.

- Wrapping & Vacuum Forming (PET Film Roll): Perfect for seamless edges, curves, and 3D components.

This compatibility allows factories to produce a wide range of cabinet styles while maintaining stable quality, making PET Film a future-ready choice for manufacturers.

5. Global Adoption Is Accelerating

Cabinet manufacturers worldwide are shifting toward PET Film because it delivers:

- A premium appearance

- Strong durability

- Eco-friendly performance

- Cost-efficient production

- Wide design possibilities

These advantages have made PET Film a preferred material not just for kitchens, but also wardrobes, bathroom cabinets, and commercial interior projects.

WellP: Your Sustainable Partner for Next-Generation PET Film

At WellP, we are committed to developing environmentally responsible PET Film solutions that support the next chapter of cabinet design.

Our PET Film collections offer:

- Super Matte, Skin Matte, High Gloss, Metal Series, and textured finishes

- Low-VOC, recyclable, and odor-free materials

- Superior scratch, stain, and fingerprint resistance

- Consistent color and surface quality

- Formats suitable for both flat lamination, wrapping and vacuum forming

- Custom color development for brand or project needs

By integrating advanced technology and sustainable practices, WellP helps manufacturers create cabinets that are beautiful, durable, and aligned with global eco-conscious design trends.If you're looking for a durable, visually compelling, and sustainable material for cabinet surfaces, PET Film is one of the best choices on the market.

Ready to enhance your next PET Film project?

Contact WellP to explore our full PET Film collection or request samples.

Home

Home How PET Film Enhances Modern Cabinet Design: A Complete Guide for Manufacturers, Designers, and Homeowners

How PET Film Enhances Modern Cabinet Design: A Complete Guide for Manufacturers, Designers, and Homeowners