Best Surface Materials for Modern Interior Doors

17 Dec,2025

17 Dec,2025

In modern interior design, the door is no longer a background element. As spaces become more refined and architectural, the surface material of an interior door plays a decisive role in both visual continuity and long-term performance.

Choosing the right door surface material today requires more than aesthetic preference. Designers, manufacturers, and developers are increasingly evaluating materials through a broader lens—durability, consistency, sustainability, and suitability for modern production processes.

Among the most commonly specified interior door finishes, four options dominate the conversation: PET film, paint, PVC film, and veneer. Each has its place, but their differences matter more than ever.

What Modern Interior Doors Demand from Surface Materials

Before comparing materials, it is important to clarify what defines a “modern” interior door today:

- Clean, uninterrupted surfaces

- Consistent color and texture across door and wall systems

- Resistance to everyday wear, touch, and cleaning

- Compatibility with minimalist and architectural design languages

- Increasing emphasis on environmental responsibility

With these criteria in mind, the strengths and limitations of each material become clear.

Paint: Familiar but Increasingly Challenged

Paint has long been the default finish for interior doors, particularly in residential projects. It offers flexibility in color selection and can achieve a clean appearance when newly applied.

However, paint presents several challenges in modern interiors:

- Surface consistency is difficult to maintain across large production batches

- Visible imperfections, fingerprints, and wear appear quickly

- On-site or post-installation touch-ups are often required

- Long-term durability is limited in high-traffic environments

While paint remains suitable for certain applications, it increasingly struggles to meet the performance expectations of contemporary door systems.

PVC Film: Functional but Limited

PVC film gained popularity as a cost-effective alternative to paint, offering improved scratch resistance and easier processing.

That said, PVC films come with notable limitations:

- Surface appearance often lacks refinement, especially in matte finishes

- Plastic-like visual characteristics can conflict with high-end interiors

- Environmental concerns and regulatory pressures continue to grow

- Aging and discoloration may occur over time

For projects prioritizing economy over longevity or sustainability, PVC may still be considered—but its role in premium interiors is diminishing.

Veneer: Natural Beauty with Inherent Variability

Veneer remains valued for its natural appearance and warmth, particularly in spaces seeking a traditional or organic aesthetic.

However, veneer also introduces challenges:

- Natural variation makes color and grain consistency difficult

- Sensitivity to humidity and temperature changes

- Higher material waste and more complex production processes

- Limited compatibility with flush or ultra-minimal door designs

In modern architectural interiors that emphasize uniformity and restraint, veneer can feel visually and technically restrictive.

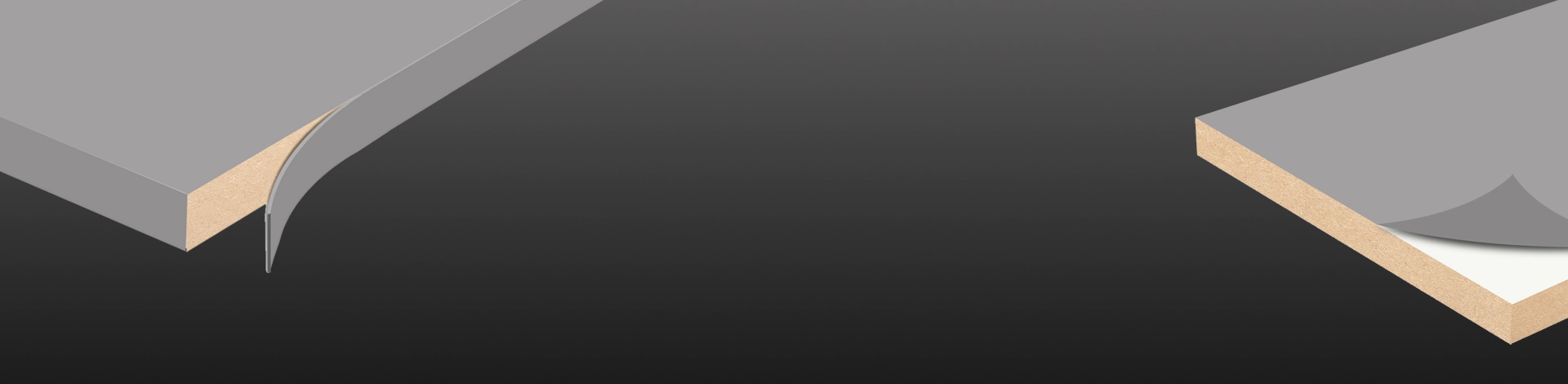

PET Film: A Surface Material Designed for Modern Doors

PET decorative film has emerged as a material specifically aligned with the demands of contemporary interior doors.

Why PET Film Stands Apart

- Consistent aesthetics: Stable color and uniform texture across large surfaces

- Durability: Excellent resistance to scratches, stains, and abrasion

- Low maintenance: Easy to clean, with advanced anti-fingerprint options

- Design flexibility: Available in solid colors, super matte finishes, and refined textures

- Sustainability: PET is recyclable and suitable for low-emission interiors

From flush doors to concealed systems and integrated door-wall applications, PET film supports the design language shaping modern spaces.

A Practical Comparison of Door Surface Materials

| Criteria | PET Film | Paint | PVC Film | Veneer |

| Surface consistency | Excellent | Moderate | Moderate | Low |

| Scratch & wear resistance | High | Low | Medium | Medium |

| Maintenance | Low | High | Low | Medium |

| Design suitability | Modern, minimalist | Traditional | Functional | Natural |

| Environmental profile | Strong | Moderate | Weak | Variable |

Why the Industry Is Moving Toward PET Film

The growing preference for PET film is not driven by fashion, but by practicality. As interior doors evolve into architectural surfaces, the material behind them must perform quietly and reliably over time.

PET film offers a rare balance—a refined appearance, dependable durability, and a responsible material profile—that few alternatives can match simultaneously.

WellP's Approach to Door Surface Materials

At WellP, we view PET film not as a decorative add-on, but as a surface solution developed for modern interiors. Our PET decorative films are engineered to support interior door applications across residential, commercial, and architectural projects, offering stable quality and design consistency.

For manufacturers and designers seeking door surface materials that align with today’s expectations—and tomorrow’s standards—PET film represents a thoughtful and future-ready choice.

Final Thoughts

Selecting the best surface material for modern interior doors is ultimately about alignment: alignment with design intent, production realities, and long-term use.

As interior architecture continues to favor clarity, restraint, and durability, PET film is increasingly proving itself not as an alternative, but as a new benchmark.

Home

Home The Future of Interior Doors: Why PET Film Is Gaining Popularity

The Future of Interior Doors: Why PET Film Is Gaining Popularity