What is Excimer Curing? The Science Behind Ultra-Matte Surfaces

14 Jan,2026

14 Jan,2026

In the world of high-end interior design, "Matte" is no longer just a trend—it is a standard. From luxury kitchen cabinets to sophisticated wall paneling, the market is demanding surfaces that are dead-flat, non-reflective, and visually profound.

However, traditional matte surfaces have always had two major enemies: Fingerprints and Scratches.

If you have ever touched a matte black cabinet only to leave a greasy smudge that refuses to wipe off, you have experienced the limitations of older technology. But there is a solution that is changing the industry. It is called Excimer Curing Technology.

At WellP, we leverage this advanced process to create our premium Ultra-Matte PET films. But what exactly is it, and why should furniture manufacturers and designers care? Let's dive into the science.

The Old Way: Why Traditional Matte Failed

To understand the innovation, we first need to look at the past. Traditionally, to create a matte finish, manufacturers added microscopic particles (like silica) to the coating.

Think of it like scattering rocks on a smooth road. These particles created a rough surface that scattered light, reducing gloss. While effective at reducing shine, this method had flaws:

- The "Chalky" Look: The particles often made dark colors look hazy, grey, or "milky."

- Poor Stain Resistance: The rough texture trapped oils and dirt.

- Burnishing: Over time, cleaning or rubbing the surface would polish these particles smooth, creating shiny spots.

The New Way: Excimer Curing Technology

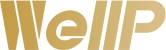

Excimer Curing does not rely on adding particles. Instead, it uses high-energy UV light to physically alter the structure of the surface at a microscopic level.

Here is the simplified, step-by-step process of how we manufacture WellP Ultra-Matte films:

1. The Application

We apply a specialized UV-curable coating onto the PET base film.

2. The "Micro-Folding" (The Magic Moment)

The film enters a chamber filled with Nitrogen (to remove oxygen) and is exposed to 172nm UV light. This specific wavelength has very low penetration power. It cures only the very top skin of the coating instantly, while the layer underneath remains liquid.

This rapid curing causes the top skin to shrink and form millions of microscopic folds.

3. The Final Cure

The film then passes under standard UV lamps to cure the deeper layers, "freezing" those micro-folds in place permanently.

Why "Micro-Folds" Create the Perfect Ultra-Matte

This unique "folded" structure is what gives WellP PET films their superior properties:

1. True Ultra-Matte Finish (<2GU)

The random micro-folds scatter light perfectly in every direction. This results in an extremely low gloss level—often below 2 Gloss Units. There is zero reflection, which ensures that colors appear deep, saturated, and pure. Black looks truly black, not dark grey.

2. The "Lotus Effect" (Anti-Fingerprint)

Because the surface is made of micro-folds, the contact area for your fingertip is drastically reduced. Oils and moisture sit on the "peaks" of the folds rather than smearing across the surface. This makes the film super-hydrophobic and exceptionally easy to clean.

3. Extreme Durability

Despite its silky appearance, the cross-linked chemical structure is incredibly hard (3H-4H hardness). It resists scratches and abrasion far better than standard painted surfaces, ensuring the matte finish remains consistent over years of use.

The WellP Advantage

Not all Ultra-Matte films are created equal. Precision control over the oxygen levels and UV intensity is critical.

At WellP, our state-of-the-art Excimer lines ensure:

- Visual Uniformity: No "clouding" or uneven gloss spots across the roll, which is critical for large-scale wall paneling or cabinetry projects.

- Flexibility: Unlike some hard coatings that crack when bent, our formulation balances hardness with the flexibility needed for membrane pressing and profile wrapping.

Conclusion

Excimer Technology is not just a buzzword; it is the future of decorative surfaces. It bridges the gap between aesthetic luxury (the Ultra-Matte look) and functional performance (durability and cleanliness).

Ready to see the difference?

Don't just take our word for it. [Contact us today] to request a sample of our Excimer-cured Ultra-Matte PET films and experience the technology firsthand.

Home

Home Beyond the Surface: Unveiling the Future of Interiors with PET Film

Beyond the Surface: Unveiling the Future of Interiors with PET Film